Using optical fiber fusion machine for optical fiber fusion is one of the mainstream methods of optical fiber field termination, so there are many kinds of optical fiber fusion machine in the market, which is dazzling.

How to choose a cost-effective optical fiber fusion machine has become a headache for many skilled workers.

About Optical Fiber Fusion Machine.

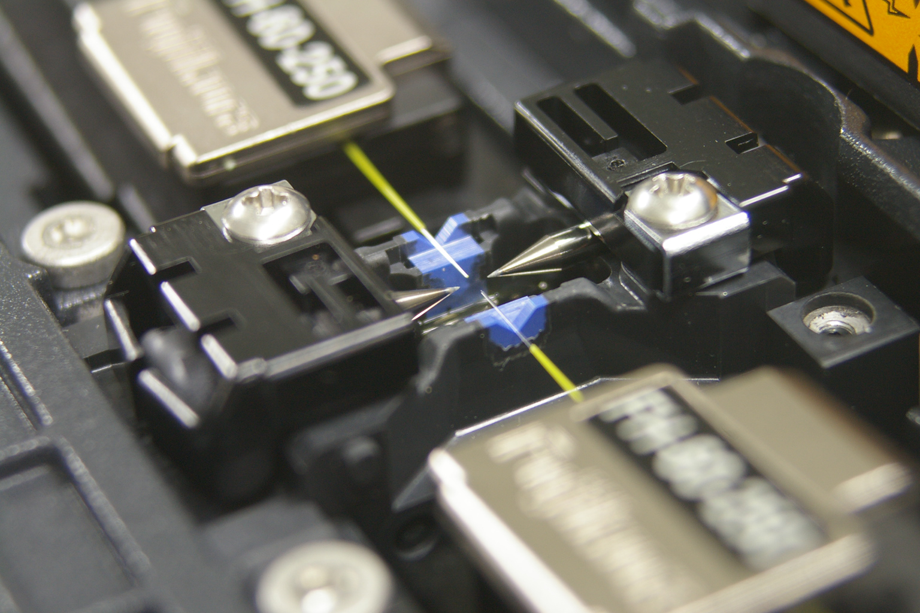

Optical fiber fusion splicing machine is mainly used for the construction and maintenance of optical cable in optical communication, so it is also called optical cable fusion machine. Its general working principle is to use high-voltage arc to melt two optical fiber sections while using high-precision motion mechanism to gently advance two optical fibers, so that it can be fused into one, so as to realize the coupling of optical fiber mode field.

From this we can see that the alignment degree of the two optical fibers is an important factor to determine the fusion quality of the optical fiber. the higher the alignment degree of the optical fiber is, the better the fusion quality of the optical fiber is.

Alignment mode of optical fiber fusion splicing machine.

Core alignment.

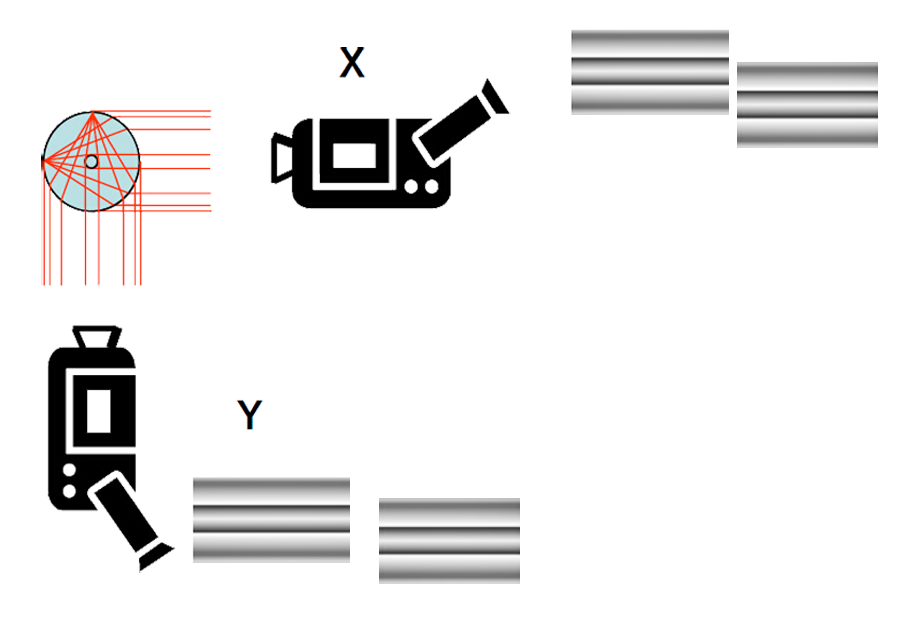

The core alignment optical fiber fusion machine uses CDS,Core Detection System, sometimes called PAS,Profile Alignment System, with six motors and two CCD cameras built in, and the fiber is aligned through a side projection system.The alignment process of the optical fiber is as follows: the light emitted by the red light source inside the welding machine irradiates the optical fiber through the reflector, converges into the objective lens, and then images on the CCD,Charge Coupled Device of the X and Y cameras. Because of the different refractive index of the core and cladding, the gray level of the image on the CCD,Charge Coupled Device is different, forming bright and dark stripes, and these stripes are aligned by a certain algorithm.

Cladding alignment.

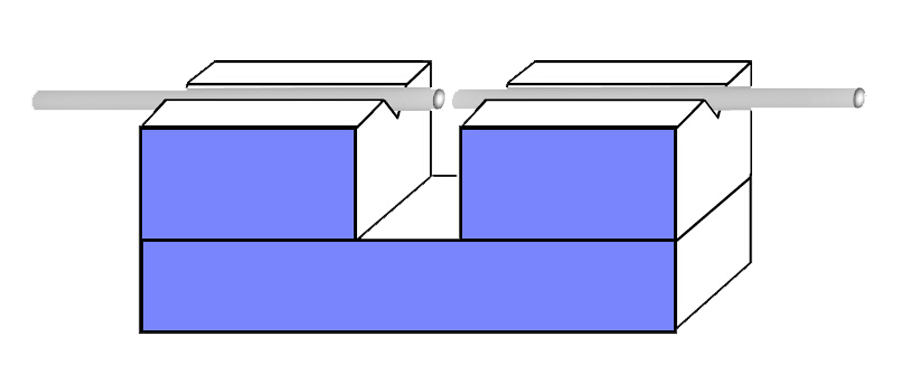

The cladding alignment optical fiber fusion machine is equipped with two motors and a camera. The optical fiber alignment process is as follows: the optical fiber to be fused is placed in a fixed V-shaped slot respectively, and then the camera is used to adjust the position of the fixed V-shaped slot according to the concentricity of the optical fiber, so that the cladding of the two optical fibers are aligned. Finally, two motors are used to promote the optical fiber for electrode discharge fusion.

The cladding alignment optical fiber welding machine requires high precision of fixed V-shaped grooves and must be clean and pollution-free.

In addition, because the splicing machine is aligned with the cladding of the optical fiber rather than the optical fiber, the loss of the welded optical fiber is also relatively large.

Concluding remarks.

Cladding alignment optical fiber welding machine is mainly used in optical fiber household and other occasions where the quality of optical fiber fusion is not too high, and the price is relatively cheap.